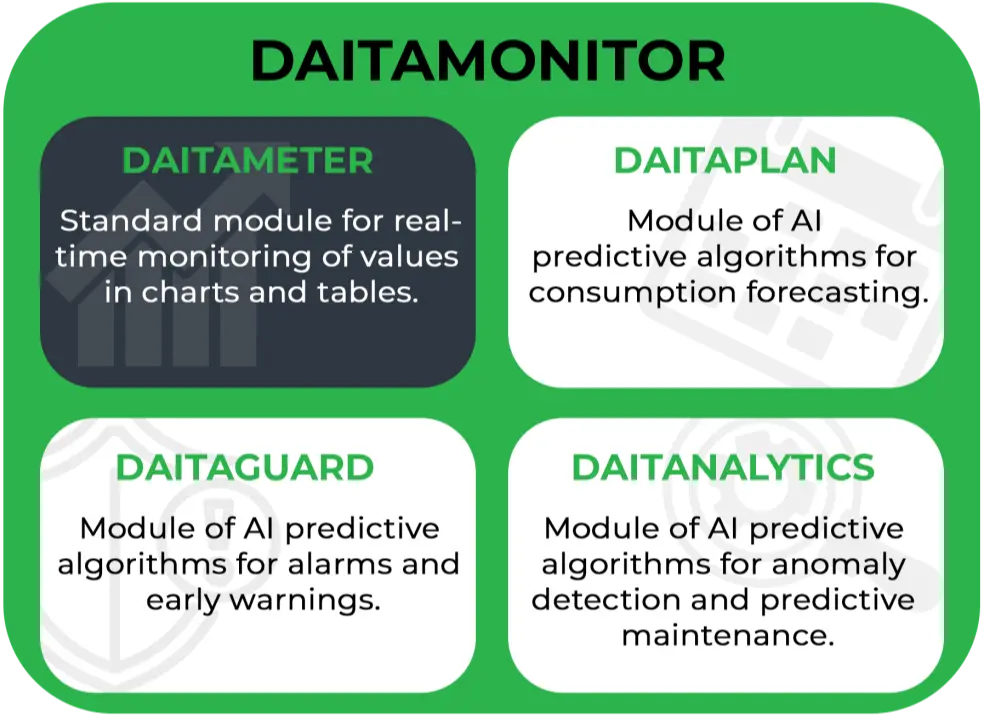

Learn More About DAITAMONITOR

DAITAMONITOR is a complex energy management system combining features of smart metering, consumption guarding, value predictions and predictive diagnostics (or preventive maintenance) using artificial intelligence to predict and analyse the monitored and gathered data. This system is highly beneficial for manufacturing companies with many machines and high energy consumption, but it can be used in office / residential buildings, communities/municipalities, electricity plants and basically at any facility which has a need for a better energy managements, saving costs and being more environmentally friendly.